In today’s manufacturing world, precision and efficiency are key to producing high-quality products. CNC (Computer Numerical Control) machines are widely used in industries to achieve this precision. A crucial part of these machines is the spindle, which directly affects the machine’s accuracy, speed, and overall performance. Over time, spindles can experience wear and tear, leading to reduced efficiency and errors in production. This is where HSD spindle repair services play a vital role. These services help maintain the performance of CNC machines and ensure consistent precision in operations.

Understanding HSD Spindle Repair

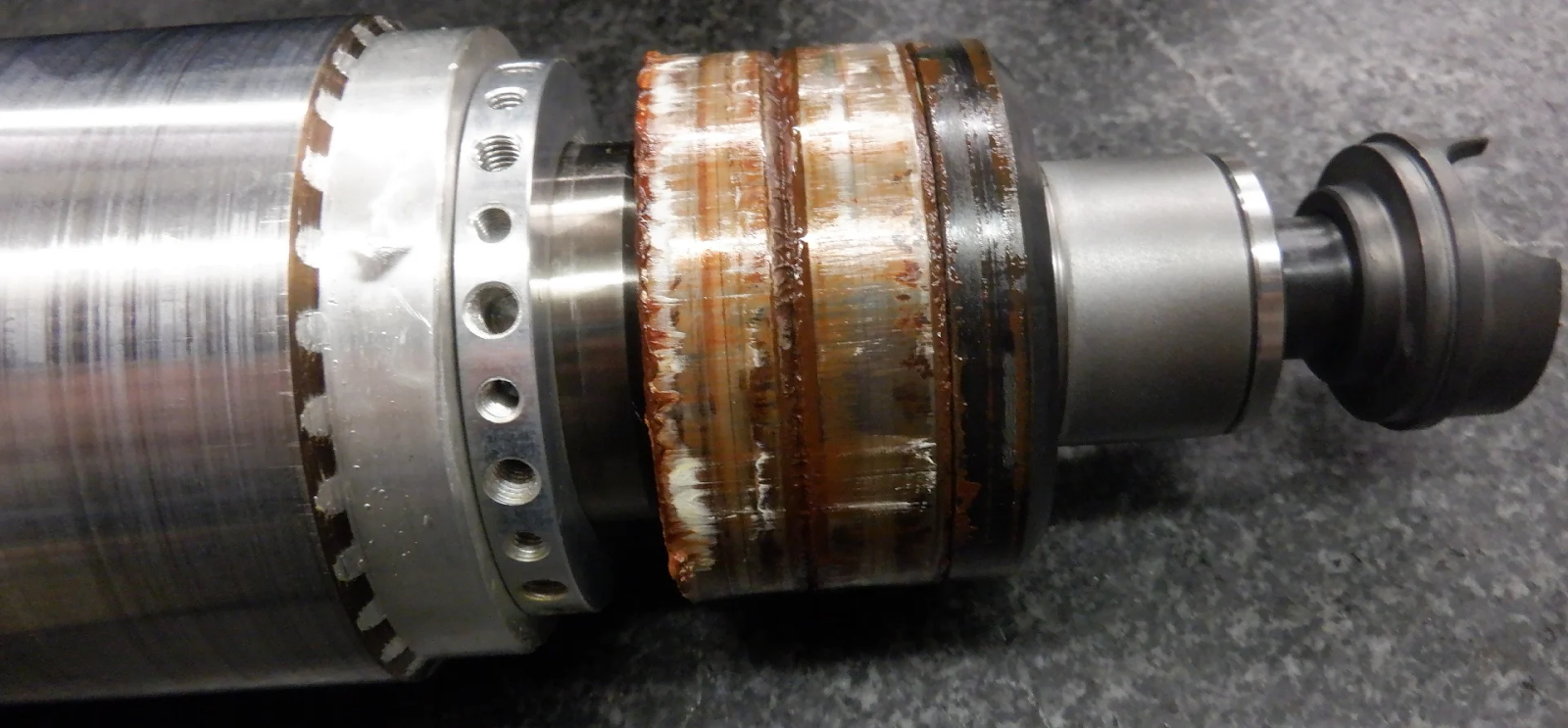

HSD spindle repair involves professional maintenance and restoration of the spindle unit in CNC machines. The spindle is responsible for rotating the cutting tool or workpiece at high speeds, and even minor issues can significantly impact machining accuracy. HSD spindle repair services inspect the spindle for problems such as imbalance, bearing wear, vibration, or overheating. They then repair or replace the damaged parts to restore the spindle’s optimal functionality. By doing so, these services extend the spindle’s lifespan and prevent unexpected breakdowns, which could lead to costly downtime.

Importance of Precision in CNC Operations

Precision is the foundation of CNC machining. Accurate measurements and consistent movements are essential for producing parts that meet design specifications. Even a slight deviation in spindle performance can lead to errors in cutting, drilling, or milling processes. When spindles operate smoothly and efficiently, machines can maintain exact tolerances and deliver high-quality outputs. HSD spindle repair ensures that CNC machines continue to function at their highest precision levels, allowing manufacturers to meet client demands and maintain a competitive edge in the market.

How HSD Spindle Repair Enhances Machine Performance

Repairing a spindle through professional services significantly improves machine performance. When a spindle is faulty or worn out, it can cause vibrations and uneven movements, which compromise the quality of the workpiece. HSD spindle repair addresses these issues by balancing the spindle, replacing worn bearings, and correcting alignment problems. As a result, the machine operates more smoothly and reliably. This improvement not only enhances the quality of machining but also increases the speed of operations, allowing manufacturers to produce more parts in less time without sacrificing accuracy.

Reducing Downtime and Maintenance Costs

One of the major advantages of HSD spindle repair is its role in minimizing downtime. Unexpected spindle failures can halt production, leading to delays and financial losses. Regular spindle maintenance and timely repair reduce the likelihood of such breakdowns. Additionally, repairing a spindle is often more cost-effective than replacing it entirely. HSD spindle repair services focus on restoring the existing spindle to peak condition, which saves money and ensures continuous operation. This proactive approach to maintenance also extends the overall lifespan of CNC machines, reducing long-term repair and replacement expenses.

Ensuring Safety and Reliability

CNC machines operate at high speeds and generate significant mechanical forces. A malfunctioning spindle can pose safety risks to operators and affect machine reliability. HSD spindle repair services help maintain safety standards by ensuring that spindles function properly. Technicians carefully inspect and test the spindle after repair to confirm its stability and performance. Reliable spindles reduce the risk of accidents and machine malfunctions, creating a safer working environment and boosting confidence in production processes.

Conclusion

HSD spindle repair services are essential for maintaining precision and performance in CNC operations. By addressing spindle issues, these services ensure that machines operate smoothly, produce accurate parts, and meet high-quality standards. They also help reduce downtime, lower maintenance costs, and enhance safety in the workplace. For manufacturers who rely on CNC machines, investing in professional HSD spindle repair is a smart decision that supports efficient, precise, and reliable production. Proper spindle maintenance is not just about fixing problems; it is about sustaining the quality and performance that modern manufacturing demands.